I: Activation method of BMS

At present, not all lithium battery protection boards need to be activated. Some protection IC requires activation. The reason is to make the protection board not work, to reduce the electrostatic discharge energy so that the lithium battery can store for a longer time.

After BMS's current limiting protection, it may need to be activated by charging or completely disconnecting the load. In addition, you can also short-circuit B- (battery negative) and P- (discharge negative), and the protection will release. Remember to avoid large sparks when short-circuiting, and remember not to bring large loads. This is because of a large voltage difference between the two ends of the discharge MOS after protection. A short-circuit touch will directly reset the D-S level of the discharge MOS to 0V, and the protection release.

II: The difference between the

common port and the split port of BMS

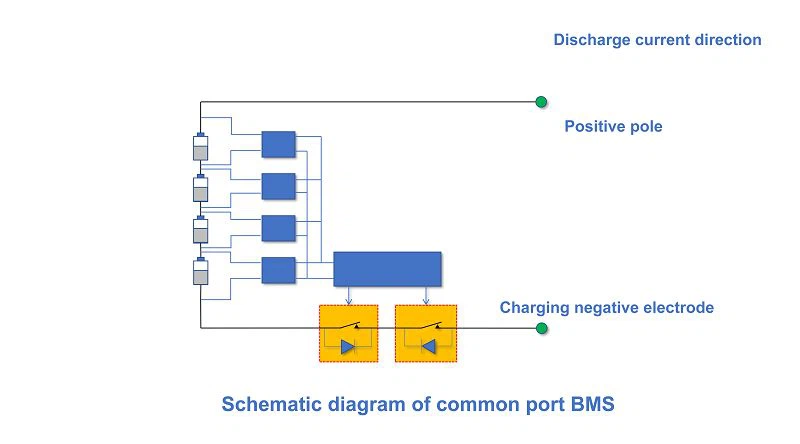

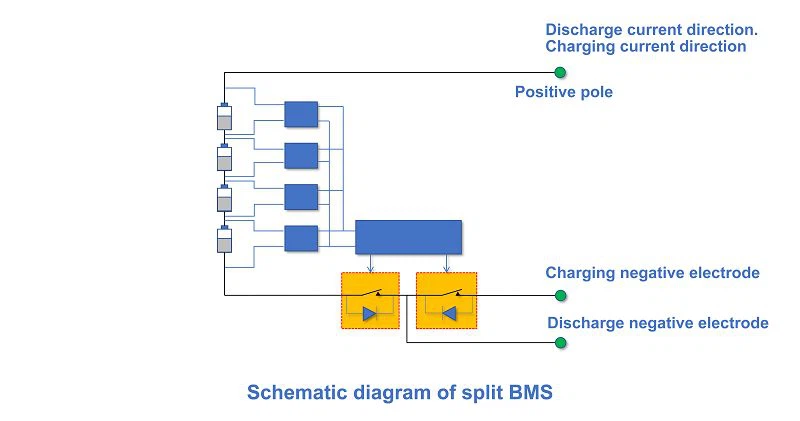

The common

port means that the charging and discharging using the same interface, with

only 2 wires; the split port means that the charging and discharging are

separated, and 3 wires are required. The disadvantage of the common port is

that the charging and discharging MOS on the protection board need to be the

same. When the battery discharge, the current will pass through the charging

MOS, and the cost, internal resistance, and heat will increase. In general, the

discharge current is much larger than the charging current. The MOS with a

smaller current is selected for the split charging MOS. The discharging and

charging do not affect each other. The disadvantage is that one more wire is

required, which is not suitable for some application scenarios. The over-current

capability of BMS is determined by the over-current capability and quantity of

the MOS tube, so the MOS tube accounts for the most cost of BMS.

How to choose the split port and

common port:

1. If the charging current is small, the discharging current is large. For example, charge 5A, discharge 20A. Recommend split mouth. (1 MOS tube for charging, 4 MOS tubes for discharging)

2. If the charging current is like the discharging current, or the charging current is larger than the discharging current. Recommend using the common port board.

III: Precautions for BMS

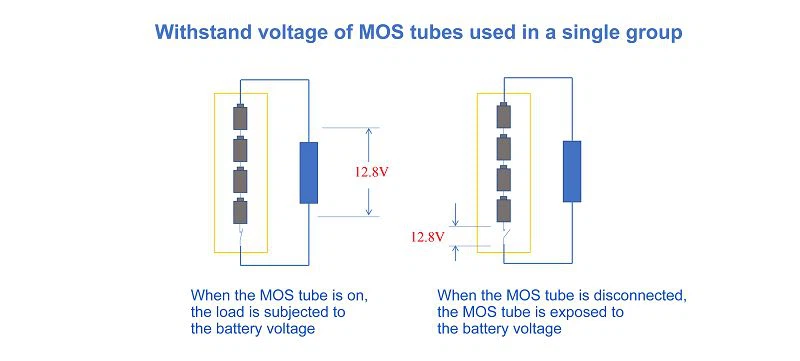

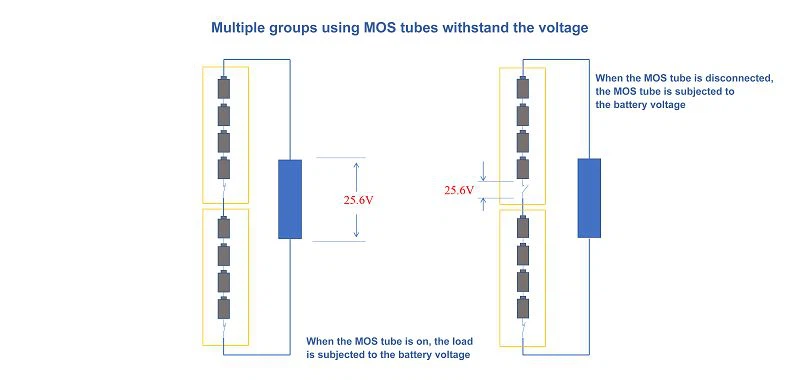

1. Cannot be arbitrarily connected in series. The switching device of the protection board uses a MOS, and MOS' price is proportional to it withstand voltage. Therefore, the withstand voltage level of the MOS is generally only higher than the voltage of the corresponding battery pack, and it will not be too large.

2. When measuring the voltage of each string, the test leads need to be placed correctly, and they will short-circuit and emit smoke;

3. When connecting the BMS, connect the cable first and insert the protection board. If the protection board insert first, it may cause the BMS to burn out;

4. Lithium battery BMS is not the bigger the better. Calculate the continuous current supply according to the load power (actual power).

5. MOS internal

resistance is relatively stable. Once the internal resistance is high, the

first thing to consider is whether the internal resistance of FUSE or PTC is

too large. If the resistance value of the component FUSE or PTC does not

change, check the BMS structure to detect the resistance value of the via hole

between the P+ and P- pads and the component surface.

6. If there is no problem with FUSE or PTC, you need to check whether the MOS is abnormal. First, determine whether there is a problem with the welding; secondly, check whether the board is bent; then put the MOS tube under the microscope to confirm whether broken; finally, test the resistance of the MOS pin with a multi-meter.

7. If the internal resistance is still high, we need to use the probe to touch the protective plate to confirm whether the contact is poor or excessive oxidation. In addition, it is also necessary to pay attention to the nickel sheets on the cell. If the number of nickel sheets on the cell is too large, the internal resistance will be too large.

IV: The future development of BMS

1. At present, lithium battery entrepreneurs focus on the full life cycle. In order to save energy, protect the environment, and maximize the use value of lithium batteries, focus on realizing the management of the battery life cycle through various measures.

2. Avoid risks, achieve functional safety, and continue to innovate intelligently.

3. Improve the battery diagnosis technology. It requires the BMS to understand the characteristics of the battery very well and can determine whether the battery fails when working or placed. Advanced battery diagnostic technology also includes measuring the consistency of the batteries, automatic activation of the battery pack, automatic repair, and other functions.

4. BMS cost has gradually become the focus of attention. Based on safety, realizing the low-cost BMS design, efforts from all aspects are needed.

V: The development process of ILUMA BMS

1. ILUMA's earliest strategy was to purchase protection boards. Later, we found many problems in the delivery time, model selection, after-sales maintenance, and other aspects of the outsourcing method.

2. The company adjusted strategic measures in a timely manner and began to develop BMS independently. The problems in the scheme, materials, processing, and testing of the BMS veneer have gradually emerged. The engineering team gradually overcomes difficulties, constantly sums up the experience, insists on innovation, and improves research and development capabilities.

3. The company has developed to this day; we have fully equipped with the ability to develop the BMS independently. The new BMS generation has improved in function and reliability.

Our advice on how to choose BMS:

1. If BMS is used to replace lead acid, no communication is required, the voltage will not be very high, the current will not be very large, and there is no requirement for series and parallel. Use general protection board.

2. If the battery voltage is 48V, 24V, or 12V, the current is high, and a communication function is required. Consider using a BMS with boot power protection or communication function.

3. For a high-voltage and high-current system (such as an energy storage system, or electric vehicle system), or a system that cannot realize by the general protection board, the BMS lithium battery management system can generally solve it.