Product Introduction

advantages

● Adaptable in design, it can be tailored to accommodate models of varying sizes, covering up to 99% of model types.

● Featuring automotive-grade A-grade battery cells, it ensures an exceptionally extended endurance exceeding 10 hours.

● The battery pack showcases a novel design equipped with a fire extinguishing device.

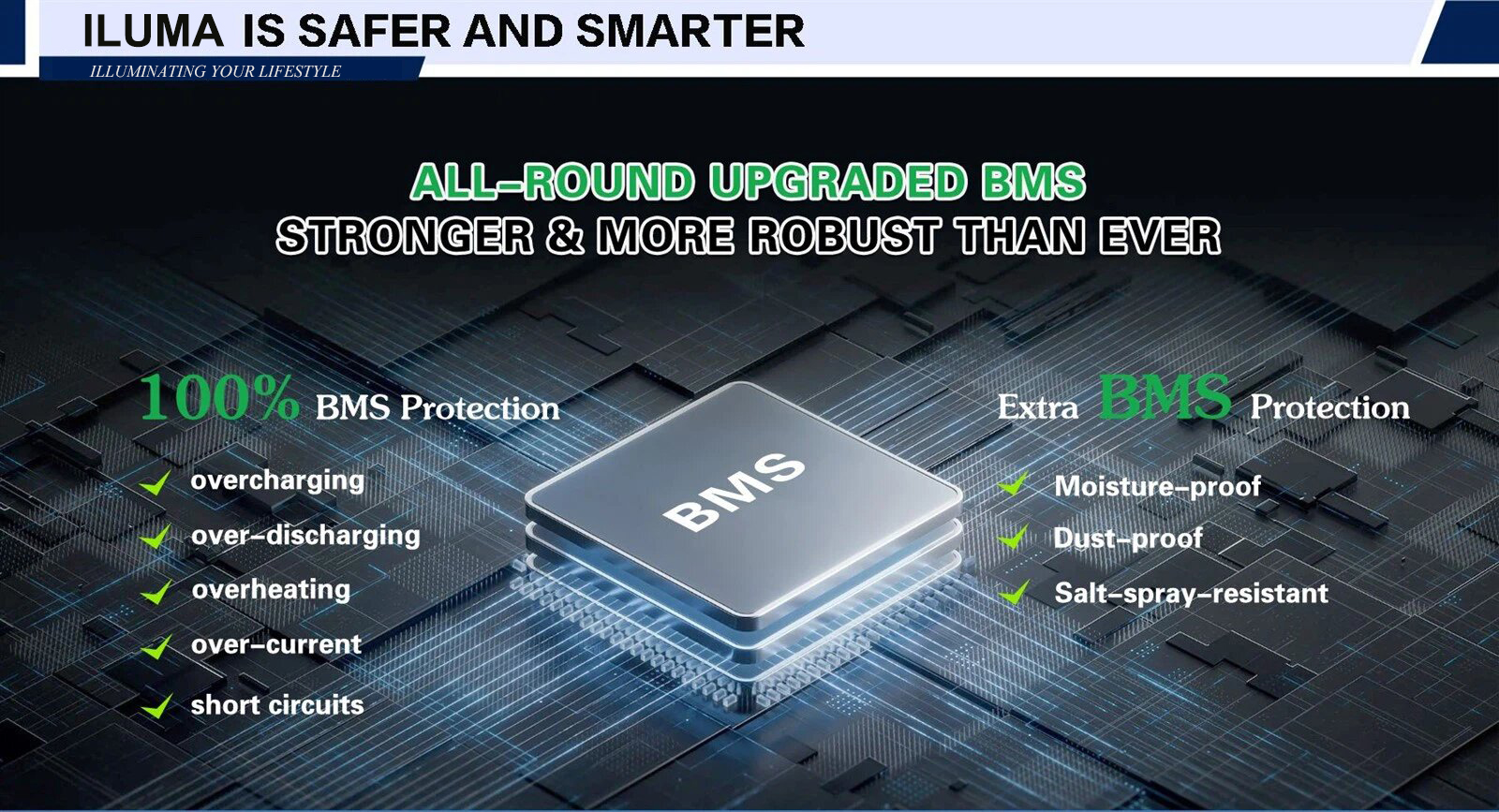

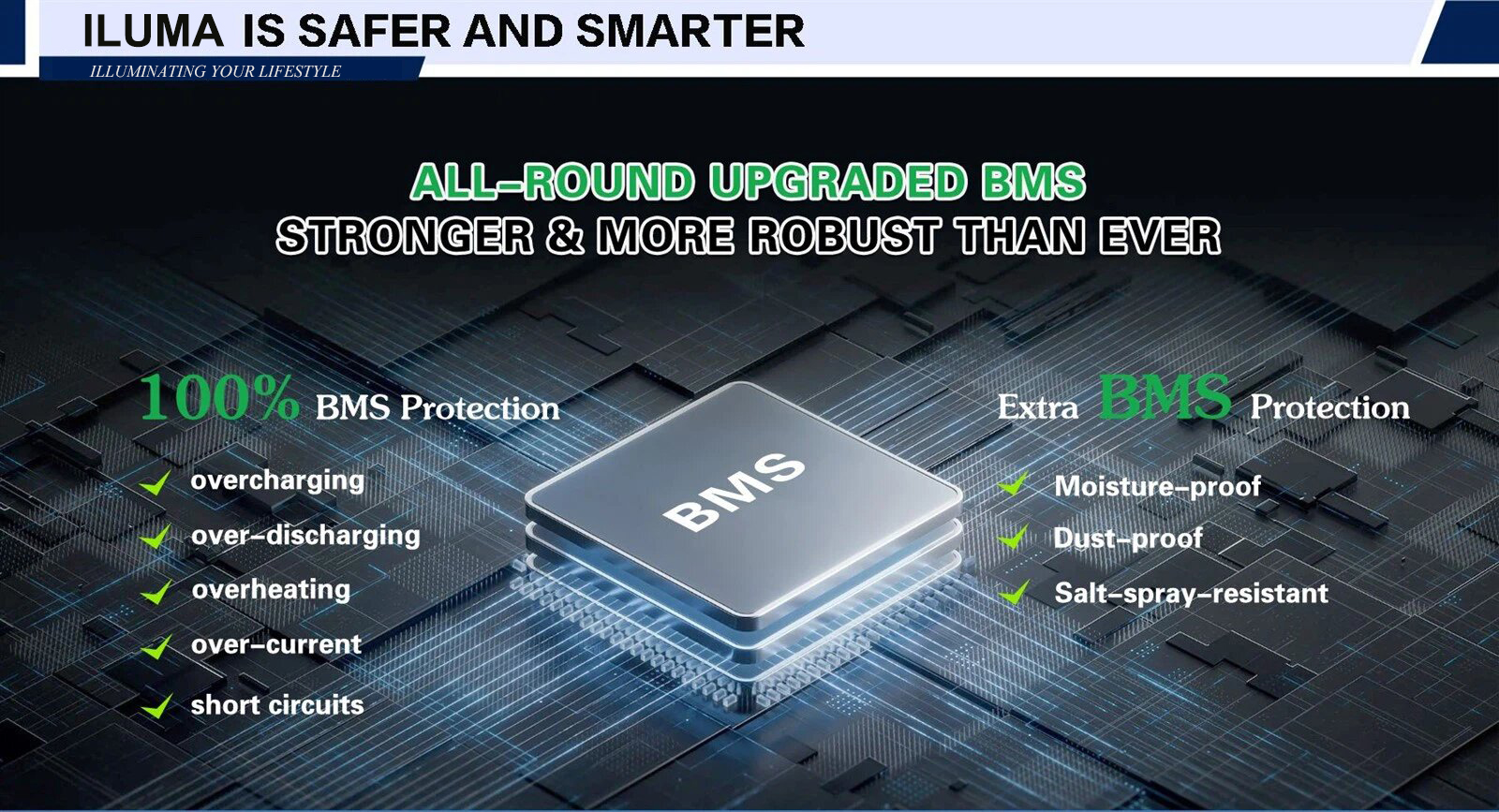

● The Battery Management System (BMS) functionality has been upgraded for intelligent balancing.

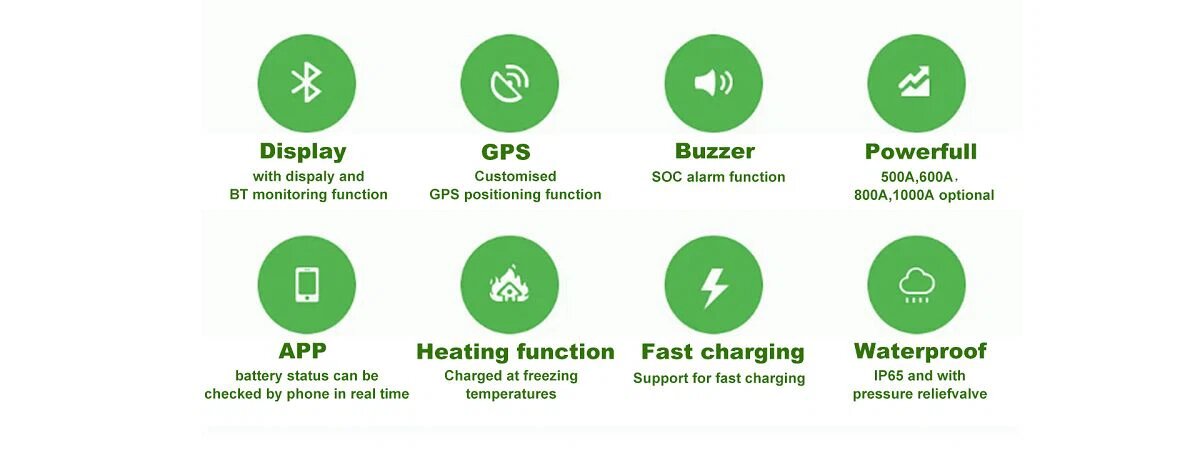

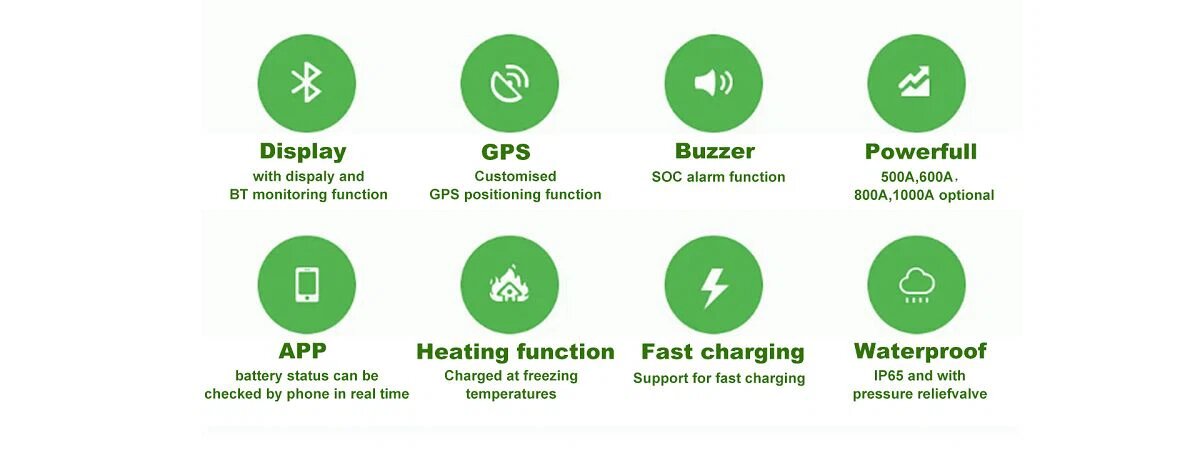

● Connectivity options include APP, Bluetooth, CAN, and RS485, enabling remote control for both switch operation and device management. Boasting ample capacity, the actual battery capacity surpasses the rated capacity.

● The high-definition intelligent display screen provides real-time monitoring of power and battery pressure differentials.

● Crafted from high-quality raw materials and advanced manufacturing technology, it comes with a 5-year warranty, extendable up to 10 years.

Characteristics

● Exceptional temperature adaptability allows for reliable operation in environments ranging from -20℃ to 60℃. The battery pack features a 1MM thick epoxy board, providing superb insulation and flame-retardant capabilities.

● Ensuring peace of mind, a high-temperature explosion-proof valve automatically and rapidly opens in the face of elevated temperatures.

● The implementation of BMS includes secondary protection functions such as temperature control protection, short circuit protection, over-current/over-voltage protection, and over-charging/over-discharging protection.

● Rigorous testing is conducted prior to leaving the factory, encompassing impact tests, extrusion tests, short circuit tests, drop tests, overcharge tests, pinprick tests, high-temperature tests, and low-temperature tests.

feature advantages

● Intermediate charging offers multi-shift availability without the need for location-specific charging or a designated charging room. Fast charging ensures shorter charging times, allowing for "Charge & Use" flexibility at any time, optimizing breaks economically.

● Compared to lead-acid batteries, the system boasts up to 20% higher electrical efficiency, resulting in fewer energy losses and reduced development inside the battery. It is an emission-free battery, generating no evolving battery gases like hydrogen and acid, eliminating the need for an extraction unit. Importantly, it does not contain toxic substances such as Cd, Pb, or Hg.

● For most two-shift applications, there is no requirement for a second battery, leading to higher vehicle availability, cost savings, and time efficiency. The absence of battery changes and charging room needs further contributes to these advantages.

● The system requires no battery maintenance, eliminating tasks like water refilling and battery cleanup. Additionally, there is no need for battery control or electrolyte circulation, streamlining operational requirements.

Our unique product advantages:

● Utilizing an automotive-grade sheet metal bracket ensures a stable battery module with commendable anti-vibration performance.

● The incorporation of advanced MOS tubes with low internal resistance facilitates high-current operations.

● The battery casing, constructed from premium PP material and employing full-automatic heat-sealing technology, guarantees resistance to dust and high temperatures without deformation.

● The battery pack exhibits outstanding consistency, achieved through either welding or soft connection, and is equipped with a deep discharge recovery function.

● An advanced formation process is implemented to ensure a balance of the battery pack, maintaining consistency and stability.

Our factory's advantages

ILUMA is a professional lithium battery solution manufacturer, with more than 15 years of experience in lithium battery packs. R&D service team 40+, providing customers with optimal battery solutions. ILUMA adopts well-known brands of batteries, and CATL, EVE, BYD, etc. Self-R&D lithium battery monitor display, can show the real-time battery operation data, and realize voice broadcast for system and error alarm which can reminder the driver of the operation condition and then make right response. For the special work condition of industrial car, ILUMA customize the high discharge rate lifepo4 battery- high discharge rate, efficient energy storage, long cycle-life, high safety performance, wide adaptability, and can meet 90% capacity range.

Patent certificates and CE/UN38.3/ISO9001:

Professional R & D Team

Case presentation:

Compatible With All Kinds Of Forklift Brands

24 volt forklift battery charger

Intelligent charging, support CAN/RS485 communication protocol, IP67 grade waterproof, automatic shutdown when fully charged, all-aluminum shell with good heat dissipation performance.

Installation

1. Before assemble, please check the battery volt and SOC (30%-90%) are in the normal value.

2. Please check the positive and negative pole of the connector and storage system are matched.

3. Handle with care, collision avoidance.

4. First, make sure that the discharge plug is in place and there is no gap between the connector.

5. Secondly, the pre-charging detection line is connected to the vehicle open load correct pole, no open connected to the discharge positive electrode.

6. Pull up the stop button and long press the start button 3S until the display displays the battery information and the sound of relay absorption, and the discharge port output voltage is completed.

7. Press the stop button, the display is off, the relay is off, and the power is complete.

FAQ

1. How Much Does A 51.2 Volt Forklift Battery Weigh??

It's important to note that the weight of a 51.2-volt forklift battery can vary based on several factors, including its capacity, type (lead-acid or lithium-ion), and specific design. For instance, a 51.2-volt 525Ah battery is estimated to weigh around 450 kg. However, the actual weight may differ for different brands, models, or configurations. It's advisable to check the specifications provided by the manufacturer for precise information regarding the weight of a specific 51.2-volt forklift battery.

2.Is it necessary to replace lead-acid batteries with lithium iron phosphate batteries for electric forklift trucks?

While the upfront cost of lithium batteries is generally higher, the total cost of ownership over the lifespan of the battery may be lower due to factors such as longer life, reduced maintenance, and improved efficiency.

Consider the specific needs of your forklift application. If factors like weight, fast charging, and longer lifespan are critical for your operation, lithium batteries might be a more suitable choice.

Check if your electric forklift truck is compatible with lithium batteries. Some forklift models may require modifications or retrofits to accommodate lithium battery systems.

If you choose lithium batteries, ensure that your charging infrastructure is compatible. LiFePO4 batteries may have different charging requirements compared to lead-acid batteries.

3.What Is the Difference Between 51.2V And 80V electric Forklifts?

51.2V Forklifts:

These forklifts operate on a 48-volt electrical system. They are commonly used for lighter to medium-duty applications. Typically, 51.2V forklifts are used for lighter loads and lower-intensity tasks. They may have a lower lifting capacity and may be suitable for indoor applications with moderate usage requirements. 51.2V forklifts may have a shorter charging time compared to higher-voltage models. Generally, 51.2V forklifts may be less expensive upfront compared to their 80V counterparts. Suited for lighter industrial tasks and indoor applications.

80V Forklifts: These forklifts operate on an 80-volt electrical system. They are generally more powerful and are suitable for heavier-duty applications.80V forklifts are designed for heavier lifting and more demanding tasks. They offer higher power and performance capabilities, making them suitable for heavy-duty outdoor applications, such as in warehouses with high stacking requirements or in construction environments. Designed for heavy-duty outdoor applications, such as construction sites, large warehouses, or ports.

When choosing between a 48V and an 80V forklift, it's essential to consider the specific requirements of your application, including the weight and size of the loads you'll be handling, the operating environment, and the intensity of usage.

4.How Do You Match a Forklift Battery and Charger??

Identify the voltage requirement of your forklift. Common voltages include 24V, 36V, 48V, and 80V. This information is crucial for selecting a compatible charger. Determine the ampere-hour (Ah) capacity of the forklift battery. Ensure that the charger's charging rate is suitable for the battery. Check that the charger and battery connectors are compatible.