Product Introduction

advantages

● Flexible design, can be customized according to the size of the model, adapt to 99% model.

● Automotive-grade A-grade battery cell, ultra-long endurance ≥ 10 hours.

● New design of battery pack with fire extinguishing device.

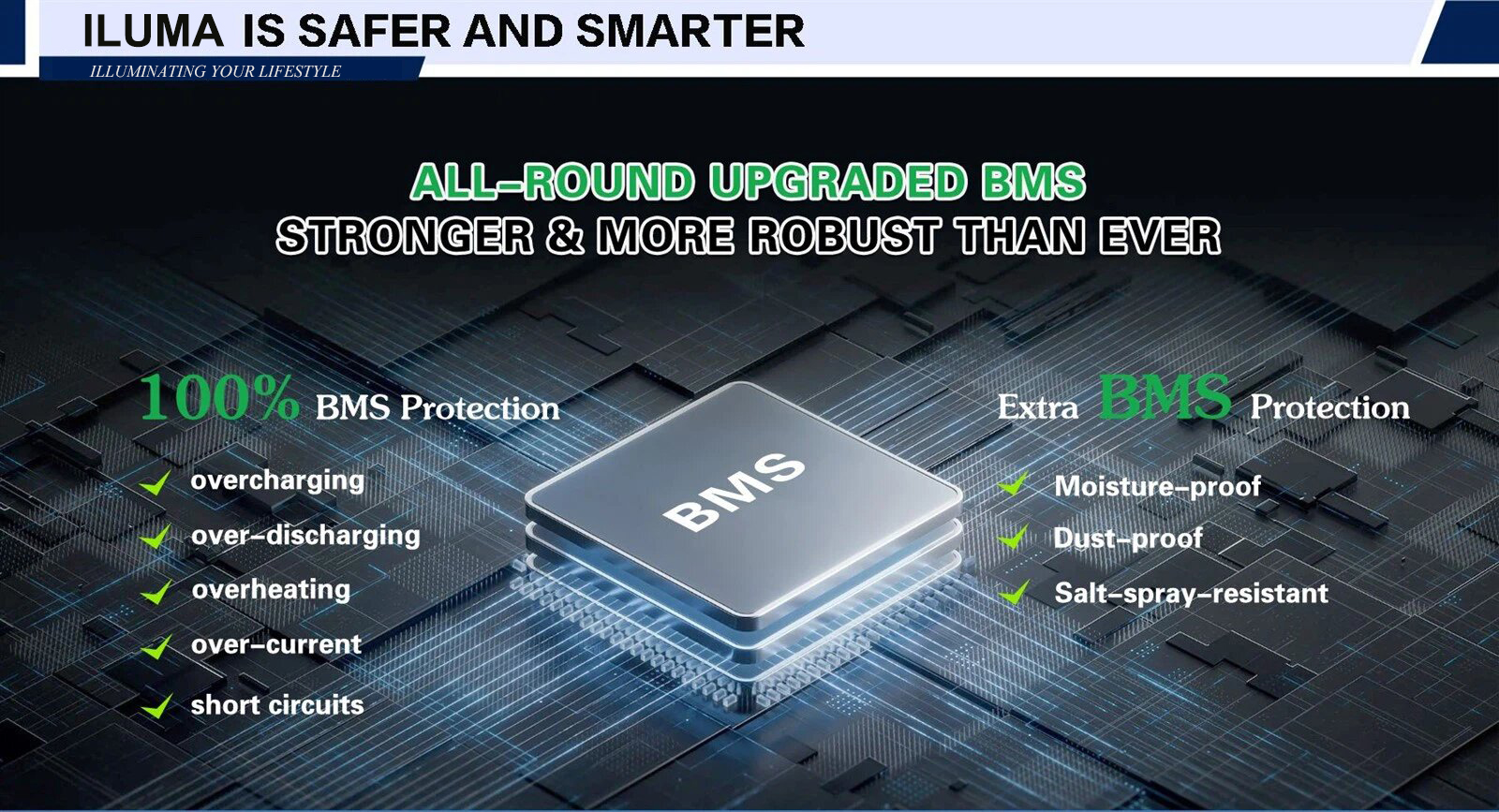

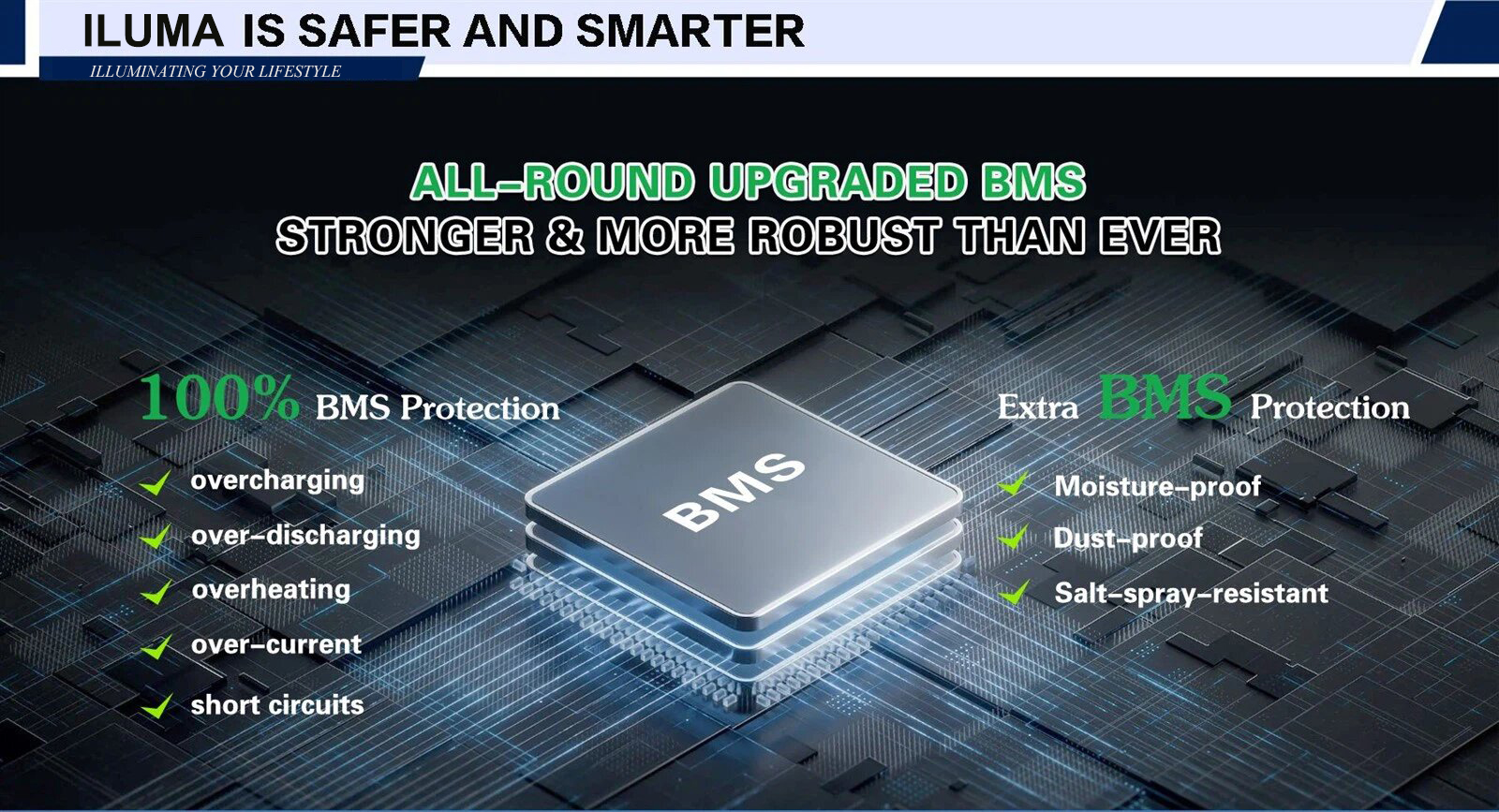

● BMS function upgrade, intelligent balance.

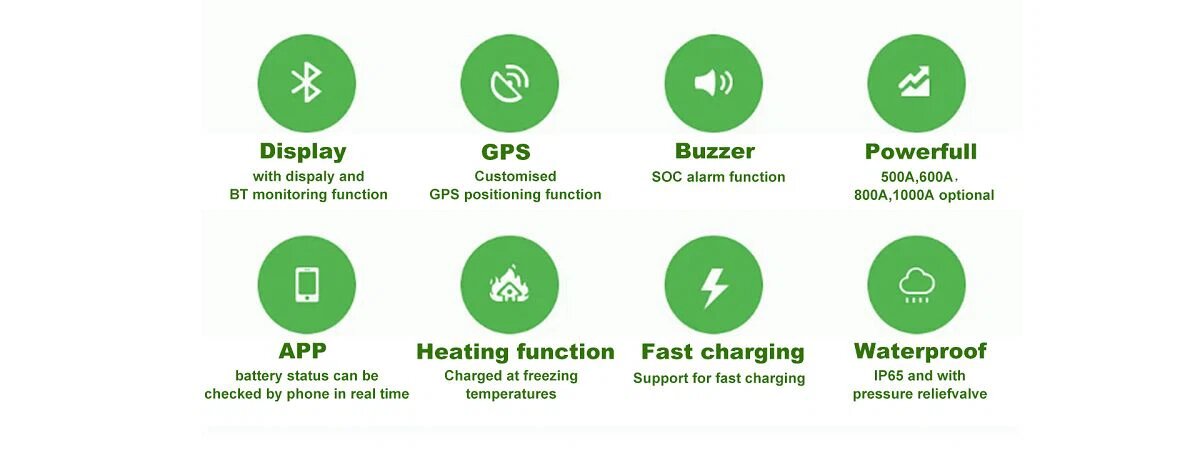

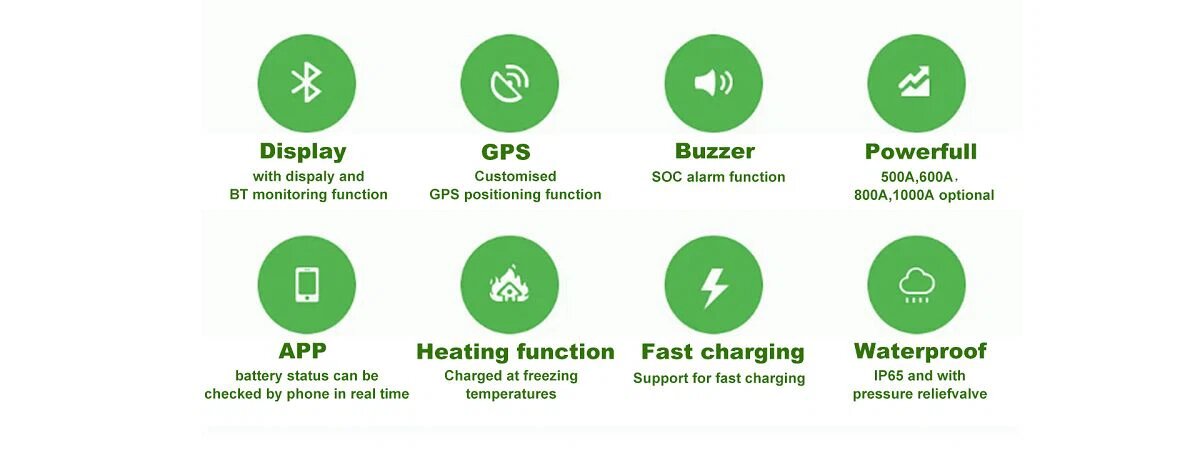

● APP/Bluetooth/CAN/RS485, support remote control of the switch and device management.

● Sufficient capacity, actual battery capacity ≥ rated capacity.

● High-definition intelligent display screen, view power and battery pressure difference in real-time.

● High-quality raw materials and manufacturing technology, 5-year warranty, can be extended to 10 years.

Characteristics

● Good temperature adaptability, operation in -20℃~60℃ environment.

● Battery pack adopts 1MM thickness epoxy board, super insulation, and flame-retardant ability.

● High-temperature explosion-proof valve automatically and quickly pops open when encountering high temperature, peace of mind.

● Adopt BMS secondary protection function, temperature control protection, short circuit protection, over-current/over-voltage protection, over-charging/ over-discharging protection.

● Strictly tested before leaving the factory: impact test, extrusion test, short circuit test, drop test, overcharge test, pinprick test, high-temperature test, low-temperature test.

feature advantages

● High-capacity, compared with traditional lead-acid batteries, lithium batteries are 1-2 times smaller and 2-3 times lighter at the same capacity.

● No harmful substances, friendly to the environment and human body, recyclable.

● 6500+ deep cycle lithium batteries, no memory effect, ultra-long service life.

● No maintenance, reducing maintenance and replacement costs.

Our unique product advantages:

● Automotive-grade sheet metal bracket, stable battery module, good anti-vibration performance.

● Adopt advanced MOS tube, low internal resistance, high current.

●The battery casing is made of high-end PP material, full-automatic heat-sealing technology, dust-proof and high-temperature-proof, not to be deformed.

● Excellent battery pack consistency, welding or soft connection, deep discharge recovery function.

● Advanced formation process to ensure the balance, consistency, and stability.

● Connector plugs can be customized and selected according to requirements.

● Design drawings provided to customers free of charge.

● R&D/Production/Processing customization/After-sales/All-in-one service.

Our factory's advantages

ILUMA is a professional lithium battery solution manufacturer, with more than 15 years of experience in lithium battery packs. R&D service team 40+, providing customers with optimal battery solutions. ILUMA adopts well-known brands of batteries, and CATL, EVE, BYD, etc. Self-R&D lithium battery monitor display, can show the real-time battery operation data, and realize voice broadcast for system and error alarm which can reminder the driver of the operation condition and then make right response. For the special work condition of industrial car, ILUMA customize the high discharge rate lifepo4 battery- high discharge rate, efficient energy storage, long cycle-life, high safety performance, wide adaptability, and can meet 90% capacity range.

Patent certificates and CE/UN38.3/ISO9001:

Professional R & D Team

Case presentation:

Compatible With All Kinds Of Forklift Brands

24 volt forklift battery charger

Intelligent charging, support CAN/RS485 communication protocol, IP67 grade waterproof, automatic shutdown when fully charged, all-aluminum shell with good heat dissipation performance.

Installation

1. Before assemble, please check the battery volt and SOC (30%-90%) are in the normal value.

2. Please check the positive and negative pole of the connector and storage system are matched.

3. Handle with care, collision avoidance.

4. First, make sure that the discharge plug is in place and there is no gap between the connector.

5. Secondly, the pre-charging detection line is connected to the vehicle open load correct pole, no open connected to the discharge positive electrode.

6. Pull up the stop button and long press the start button 3S until the display displays the battery information and the sound of relay absorption, and the discharge port output voltage is completed.

7. Press the stop button, the display is off, the relay is off, and the power is complete.

FAQ

1. How to charge the lithium battery in the forklift?

Step 1: charging preparation

Park the forklift truck in the charging area, and close the vehicle switch; Open the vehicle charging hatch and protective cover, and check the charging interface; Confirm the state of the charger, and check the charging gun, connecting the charging gun with the vehicle charging interface correctly.

Step 2: Charging starts

Open the lithium battery switch, charger air switch, and start switch;

Observe the charger display, charging connection, and working status;

Wait for charging confirmation, the charging current is normal, and charging starts.

Step 3: Charging end

Press the charger stop button; Confirm that the charging current display is 0A, then unplug the charging gun; Close the charging protective cover and hatch, and place the charging gun in a standardized way.

2. Can lithium batteries be charged with lead-acid battery chargers?

The charging mechanism of these two is very different, lithium batteries generally constant current and constant voltage charging method or three-stage charging, while the lead-acid battery charger uses a pulse charging method. From the perspective of long-term safety and stability, lithium batteries must still use a dedicated charger. Charger design and materials are strict, good-quality chargers are fully functional, safe, and reliable, the use temperature will not be too high, and long service life!

3. Why does the battery pack suddenly stop working when it is in use?

The possible reasons are that the power has reached the minimum lower voltage limit of the protection board, the protection board or controller stops working; or the continuous working current exceeds the design protection current of the protection board, which will make the battery pack stop working suddenly.

4.Why can't the battery pack be discharged suddenly?

Maybe there are several reasons: low voltage protection board protection; protection board damage; discharge positive and negative poles reversed; line disconnection or switch does not turn on; for the above situation, you can charge the battery pack, find the protection board or line connection problems to solve.

5. Why does the battery pack range suddenly become shorter?

The reasons for this situation are: the battery does not fully charge; the voltage and capacity difference of a single cell is high; the battery pack is short-circuited or the self-discharge is high. In response to the above, the battery pack is recharged or replaced with a bad cell to deal with the situation.

6. How to choose the right forklift battery? Which aspects need considered?

Battery voltage and capacity, the battery box size, the battery weight, the cell quality, the BMS function, and the charger. Understanding the brand and manufacturer strength, etc.